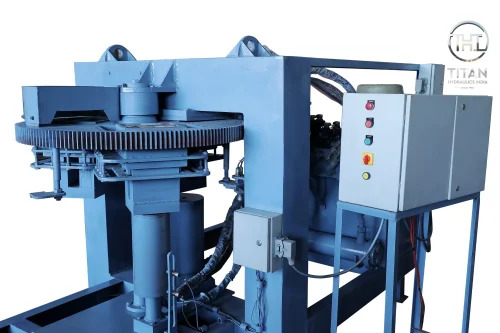

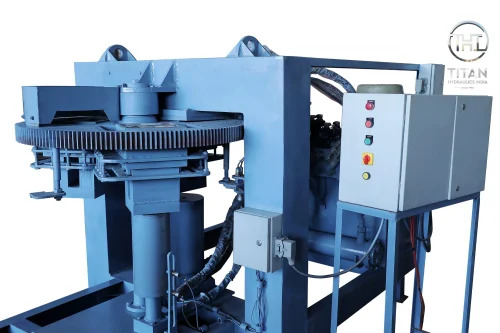

Rotary Table Fly Ash Bricks Making Machine

Price 1100000 INR/ Unit

MOQ : 1 Unit

Rotary Table Fly Ash Bricks Making Machine Specification

- General Use

- Industrial

- Automatic

- Yes

- Method

- Hydraulic Pressure

- Voltage

- 220 Volt (v)

- Feature

- High Durability

- Warranty

- 1 Year

Rotary Table Fly Ash Bricks Making Machine Trade Information

- Minimum Order Quantity

- 1 Unit

- Payment Terms

- Cash in Advance (CID)

- Supply Ability

- 100 Units Per Month

- Delivery Time

- 7 Days

- Main Domestic Market

- All India

About Rotary Table Fly Ash Bricks Making Machine

Experience rarefied excellence with our Rotary Table Fly Ash Bricks Making Machine, a trending best-seller in Indias industrial sector. Designed for matchless performance, this automatic machine boasts high durability and operates efficiently at 220 Volt (v). Utilizing a hydraulic pressure method, it guarantees robust output and top-class reliability. As a leading manufacturer and supplier, we offer a 1-year warranty with each unit. Take advantage of exclusive deals on this best-in-class machine, engineered for flawless, large-scale brick production.

Features and Applications of Rotary Table Fly Ash Bricks Making Machine

This matchless machine stands out for its high durability and advanced hydraulic pressure method, ensuring consistent and strong brick formation. It is particularly suitable for industrial-scale use, making it ideal for factories and construction sites that demand uniform quality. The Rotary Table Fly Ash Bricks Making Machine can be applied to various surfaces, offering excellent adaptability for construction projects. Its automatic operation reduces manual labor, increases productivity, and helps streamline industrial operations seamlessly.

Export Markets and Order Fulfillment Experience

Our Rotary Table Fly Ash Bricks Making Machine commands demand across leading export markets including Asia, Africa, and the Middle East. With flexible payment terms and secure packaging in robust crates, we prioritize safety in transit. Order completion is streamlined by our reliable logistics network, ensuring your shipment arrives on time. Express shipping options are available for urgent requests, guaranteeing swift delivery and maximum satisfaction for international and domestic buyers alike.

Features and Applications of Rotary Table Fly Ash Bricks Making Machine

This matchless machine stands out for its high durability and advanced hydraulic pressure method, ensuring consistent and strong brick formation. It is particularly suitable for industrial-scale use, making it ideal for factories and construction sites that demand uniform quality. The Rotary Table Fly Ash Bricks Making Machine can be applied to various surfaces, offering excellent adaptability for construction projects. Its automatic operation reduces manual labor, increases productivity, and helps streamline industrial operations seamlessly.

Export Markets and Order Fulfillment Experience

Our Rotary Table Fly Ash Bricks Making Machine commands demand across leading export markets including Asia, Africa, and the Middle East. With flexible payment terms and secure packaging in robust crates, we prioritize safety in transit. Order completion is streamlined by our reliable logistics network, ensuring your shipment arrives on time. Express shipping options are available for urgent requests, guaranteeing swift delivery and maximum satisfaction for international and domestic buyers alike.

FAQs of Rotary Table Fly Ash Bricks Making Machine:

Q: How does the Rotary Table Fly Ash Bricks Making Machine enhance brick production efficiency?

A: The machine combines an automatic rotary table system with hydraulic pressure technology, streamlining the brick-making process and ensuring high throughput with minimal supervision. This results in increased productivity and consistency in output.Q: What materials can be used with this brick-making machine?

A: The machine is designed primarily for fly ash, but it can also process other suitable raw materials widely used in the brick-making industry, such as sand, cement, and additives, ensuring versatility.Q: Where is the Rotary Table Fly Ash Bricks Making Machine predominantly used?

A: This machine is commonly used in industrial settings, such as brick factories and large-scale construction sites, where high-volume and consistent brick production is required.Q: What benefits does the 1-year warranty offer to buyers?

A: The 1-year warranty protects against manufacturing defects or operational issues, ensuring buyers receive reliable, ongoing support and service from the manufacturer or supplier.Q: When can buyers expect their ordered machine to be delivered?

A: Order completion varies based on the destination, but express shipping options can expedite delivery. Buyers are kept updated through the logistics process to ensure prompt and secure arrival of the machine.Q: How is the machine packaged for shipping?

A: For maximum safety, the Rotary Table Fly Ash Bricks Making Machine is securely packed in heavy-duty crates and materials designed to prevent transit damage during logistics operations.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Automatic Fly Ash Brick Making Machine Category

Semi Automatic Fly Ash Brick Making Plant Manufacture

Price 1200000 INR / Unit

Minimum Order Quantity : 1 Unit

Warranty : 1 Year

General Use : Industrial

Voltage : 220 Volt (v)

Feature : High Durability

Semi Automatic Fly Ash Brick Making Plant Manufacturer

Price 1100000 INR / Unit

Minimum Order Quantity : 1 Unit

Warranty : 1 Year

General Use : Industrial

Voltage : 220 Volt (v)

Feature : High Durability

Fully Automatic Fly Ash Brick Making Plant

Price 1100000 INR / Unit

Minimum Order Quantity : 1 Unit

Warranty : 1 Year

General Use : Industrial

Voltage : 220 Volt (v)

Feature : Fire Resistant

Automatic Fly Ash Brick Plant Manufacture

Price 1100000 INR / Unit

Minimum Order Quantity : 1 Unit

Warranty : 1 Year

General Use : Industrial

Voltage : 220 Volt (v)

Feature : Anti Seismic

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese